Hindalco Port Crane

LEVEL LUFFING CRANE

The Challenge

The project at hand encompassed the retrofitting and complete automation of a Level Luffing port crane—a comprehensive turnkey job requiring intricate technical expertise. The challenge was to incorporate advanced high availability features, including redundancy at multiple levels, requirements extended beyond the standard scope.

The task was intricate and time bound, it was imperative to engage the services of an exceptionally proficient vendor with a proven track record in handling such complex endeavors seamlessly, exhibiting impeccable precision in project timelines.

The Solution

The realm of bulk material handling cranes stands as a formidable challenge for automation vendors.

Velox, as a leading force in the industry has conquered and excelled in delivering exceptional solutions. Our expertise and skilled team make us the preferred choice for time-critical crane automation projects. Our expertise extends across diverse industrial crane applications, encompassing EOT (Electric Overhead Travel), Hook, and Ladle cranes, to name a few

Velox’s extensive experience in crane automation in the port environment bears witness to our ability to tackle complex projects, particularly in the port sector. We have successfully implemented automation solutions for Level Luffing cranes, Barge unloaders, ship unloaders, Rubber tyre gantry cranes, and more.

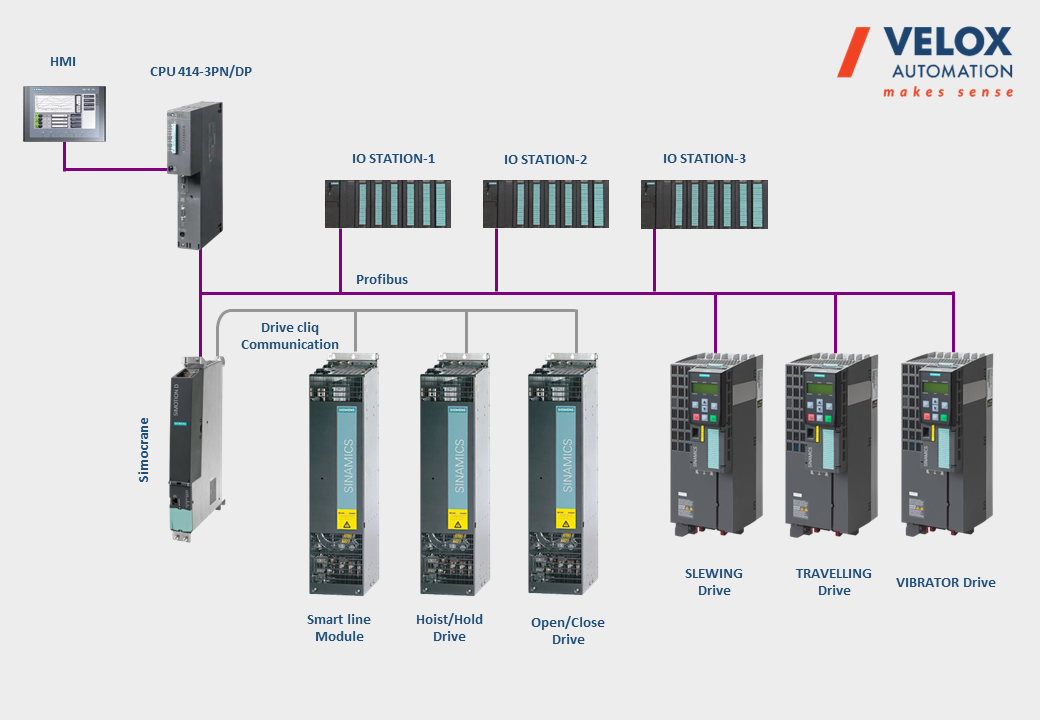

- The system employed the Siemens S7-400H CPU with the ET200M interface module for seamless integration and enhanced performance.

- To ensure reliable communication and fault tolerance, a redundant Profibus network was expertly configured between the CPU and IO station.

- Windows-based HMI was implemented for seamless monitoring and diagnostics..

- All drives were on Profibus DP with special Simocrane software.

Why Velox Solutions Makes Sense

- The system transition was seamlessly and successfully completed within a brief 3-day shutdown period.

- High system availability leads to zero downtime, ensuring uninterrupted operations

- The latest system upgrade offers improved diagnostic features and enhanced controls

- Velox offers Local support 365 days

- By keeping the load situated on the construction site, the safety and well-being of the general public and environment is ensured.

- This remarkable vehicle demonstrates remarkable adaptability, capable of traversing various terrains, including soft soils, without causing any harm to the environment.