Arcelor Mittal Nippon Steel (AMNS)

VELOX UPGRADES AMNS HOT STRIP MILL DCS SYSTEM IN JUST 3 DAYS, SAVES PRODUCTION COSTS

The Challenge

Customers typically choose to retrofit using the same OEM system. However, this project stands out as the customer decided to deviate from the norm by removing the existing Honeywell DCS and Siemens S5 PLC system. They opted for a consolidated Siemens PCS7 DCS system instead.

The primary obstacle was the need to work within a limited timeframe and space, all while operating in the same panel.

The Solution

To facilitate long-term data storage, a comprehensive configuration was implemented for archiving all process values to be accessed and analyzed for future reference and analysis. Velox was selected for the task due to their extensive experience in the field of Automation, and a proven track record in successfully executing projects.

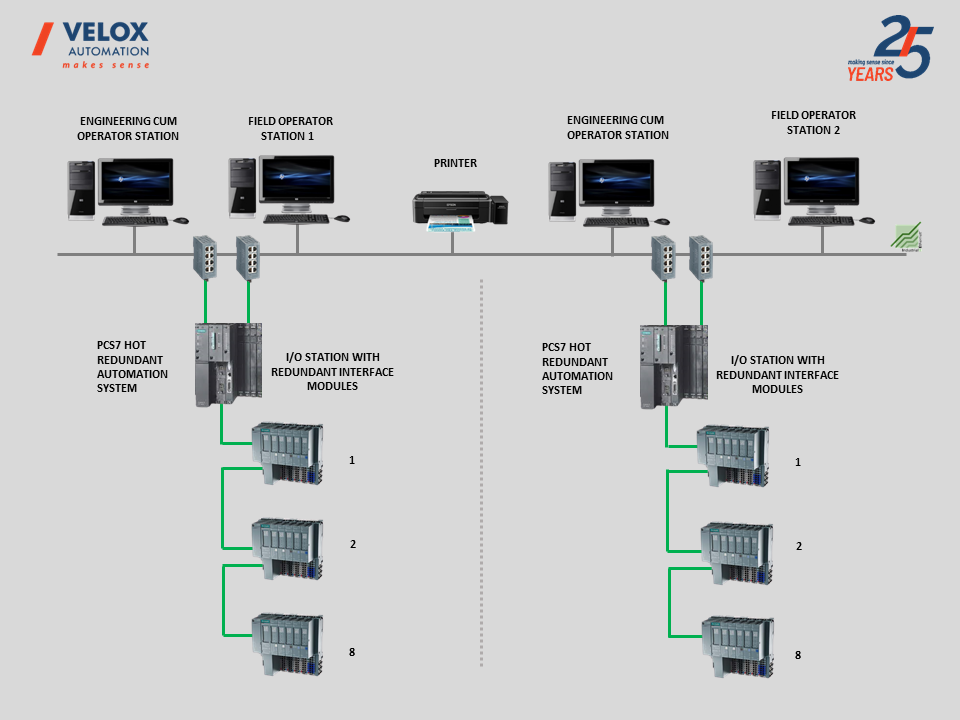

- In this setup, there were two Automation Stations, one dedicated to RHF-1 and the other to RHF-2. Each station featured hot redundant PCS7 V9.0 Controllers. The system relied on ET200SP RIO Stations, which provided a total of 2816 I/Os. Communication between the controllers and RIO Stations was established through a redundant Profinet ring.

- To support the overall infrastructure, two engineering stations and two operator stations were in place for efficient monitoring and control. The communication network was carefully designed to ensure uninterrupted data flow, utilizing Siemens Scalance switches, CP cards, and a robust fiber optic network.

- The Reheating Furnace (RHF) 1&2 at the HSM Plant had outdated Honeywell DCS systems and Siemens S5 PLC systems that required refurbishment. In order to meet the critical process requirements and ensure high reliability, Siemens PCS7 were implemented.

- One of the significant challenges of this project was the completion within a tight shutdown window of just 10 days which was achieved in lesser time.

Why Velox Solutions Makes Sense

For the Client

- The installation of the latest system effectively resolved all concerns associated with the obsolete system, including challenges related to spares availability and the need for trained service engineers. By upgrading to the new system, these issues were completely eliminated.

- It was beneficial to the client as the logic was rewritten, offline testing was done, and the system was commissioned seamlessly in a single attempt.

- The seamless performance achieved can be attributed to the implementation of the latest PCS7 V9.0 system. This advanced system played a crucial role in ensuring smooth and efficient operations.

- Client was glad to get the system up in 3 days instead of 10 days for the changes, earning ourselves an appreciation letter.

For the Environment

- Relevant technological changes reduce energy consumption.

- A greener environment and sustainable future is seen with synergizing advanced technologies for sure.